How Does A Magnetic Flow Meter Register Water Flow

Electromagnetic flow meters (or magmeters) are a type of velocity or volumetric flow meter that operate pursuant to Faraday'due south law of electromagnetic induction – which states that a voltage will exist induced when a conductor moves through a magnetic field. Magmeters tin discover the flow charge per unit of conductive fluids only. Early magmeter designs required a minimum fluidic conductivity of ane-v microsiemens per centimeter for their operation. The newer designs have reduced that requirement a hundredfold to between 0.05 and 0.one.

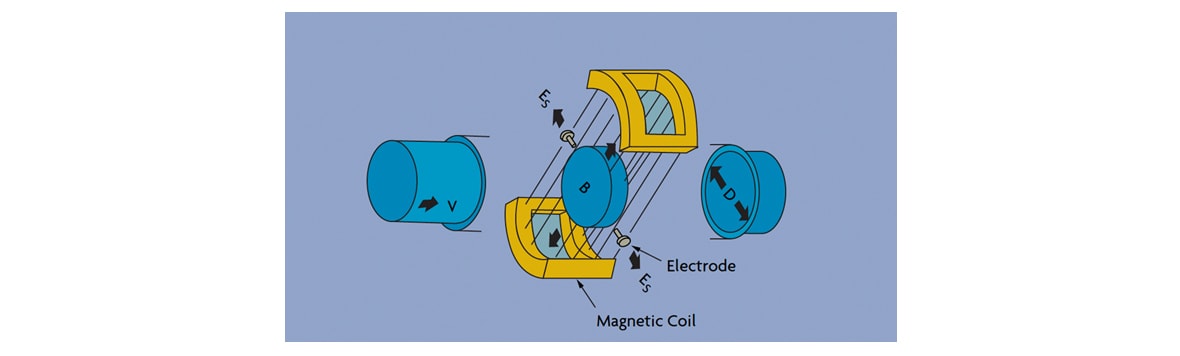

The magnetic flowmeter consists of a non-magnetic piping that is lined with an insulating material. A pair of magnetic coils is situated as shown in Effigy 1, and a pair of electrodes penetrates the pipe and its lining.

If a conductive fluid flows through a pipe of diameter (D) through a magnetic field density (B) generated by the coils, the amount of voltage (Eastward) developed across the electrodes--equally predicted by Faraday'due south law--will be proportional to the velocity (V) of the liquid. Because the magnetic field density and the pipe diameter are fixed values, they can be combined into a calibration factor (K) and the equation reduces to:

E = KV

The velocity differences at different points of the flow profile are compensated for by a point-weighing gene. Compensation is also provided by shaping the magnetic coils such that the magnetic flux volition be greatest where the signal weighing factor is lowest, and vice versa.

Manufacturers determine each magmeter'southward K factor by water calibration of each flow tube. The K value thus obtained is valid for any other conductive liquid and is linear over the entire flowmeter range. For this reason, menses tubes are usually calibrated at only one velocity. Magmeters can measure flow in both directions, as reversing management will change the polarity only not the magnitude of the signal.

Figure 1: The Magmeter and Its Components

Figure 1: The Magmeter and Its Components

The K value obtained by water testing might not be valid for non-Newtonian fluids (with velocity-dependent viscosity) or magnetic slurries (those containing magnetic particles). These types of fluids tin can bear upon the density of the magnetic field in the tube. In-line calibration and special compensating designs should be considered for both of these fluids.

Magmeter Excitation

The voltage that develops at the electrodes is a millivolt signal. This point is typically converted into a standard current (4-20 mA) or frequency output (0-ten,000 Hz) at or about the flowtube. Intelligent magnetic transmitters with digital outputs let direct connection to a distributed control system. Because the magmeter betoken is a weak one, the lead wire should exist shielded and twisted if the transmitter is remote.

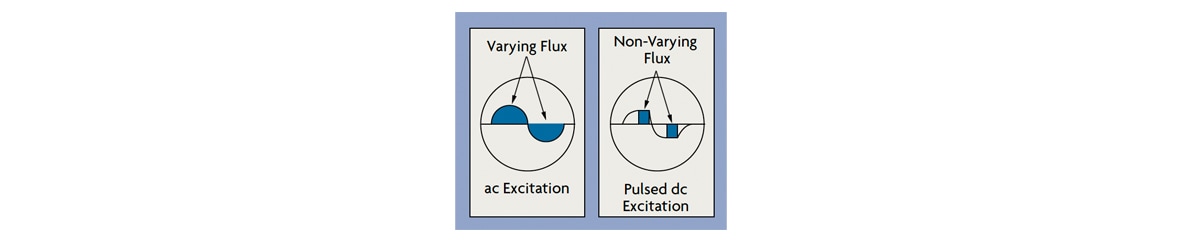

The magmeter'south coils can be powered by either alternating or directly current (Effigy 2). When air-conditioning excitation is used, line voltage is practical to the magnetic coils. As a result, the flow point (at abiding flow) volition also wait like a sine wave. The aamplitude of the wave is proportional to velocity. In addition to the flow signal, noise voltages can be induced in the electrode loop. Out-of-phase noise is easily filtered, merely in-phase noise requires that the catamenia be stopped (with the pipe full) and the transmitter output gear up to nada. The main problem with ac magmeter designs is that racket can vary with process conditions and frequent re-zeroing is required to maintain accurateness.

Figure 2: Excitation Methods

Figure 2: Excitation Methods In dc excitation designs, a depression frequency (vii-thirty Hz) dc pulse is used to excite the magnetic coils. When the coils are pulsed on (Figure 2), the transmitter reads both the catamenia and noise signals. In between pulses, the transmitter sees only the noise signal. Therefore, the noise tin can be continuously eliminated afterward each bicycle.

This provides a stable zero and eliminates zero drift. In addition to being more accurate and able to measure lower flows, dc meters are less bulky, easier to install, utilize less energy, and are nearly cost-effective than ac meters. Ane new dc design uses significantly more power than the earlier generations and thereby creates a stronger flowtube signal.

Some other new pattern uses a unique dual excitation scheme that pulses the coils at 7 Hz for zero stability and also at lxx Hz to obtain a stronger betoken. Magmeter transmitters can exist supplied with either ac or dc power. A two-wire, loop-powered dc magnetic flowmeter is besides available in an intrinsically safety design, but its functioning is reduced considering of ability limitations.

Pulsed ac meters have also been introduced recently, eliminating the zero stability problems of traditional ac designs. These devices contain circuitry that periodically disrupts the ac power, automatically zeroing out the effects of procedure dissonance on the output signal.

Today, dc excitation is used in virtually 85% of installations and ac magmeters claim the other fifteen% when justified by the following conditions:

- When air is entrained in large quantities in the procedure stream;

- When the process stream is a slurry and the solid particle sizes are non compatible and/or the solid phase is not homogeneously mixed within the liquid; or

- When the flow is pulsating at a frequency under 15 Hz.

When whatever of the higher up 3 conditions exist, the output of a pulsed dc meter is probable to be noisy. In some cases, one tin minimize the noise problem (hold the fluctuations inside 1% of setpoint) by filtering and damping the output betoken. If more than than 1 to iii seconds of damping is required to eliminate the noise, information technology is e'er better to use an ac meter.

Flow tubes, Liners, and Probes

The contiguous dimensions of flanged menstruum tubes (lay lengths) commonly meet the recommendations of the International System for Standardization (ISO). The dimensions of short form magmeters normally meet these guidelines also. Magnetic menstruum tubes and liners are available in many materials and are widely used in all the process industries, including food, pharmaceutical, mining, and metals.

Some liner materials (particularly PFA) tin exist damaged when pry bars are used while installing information technology or removing it from process piping. They can also be damaged by over-torquing the flange bolts. Liner protectors are available to aid foreclose such damage.

Any flowtube can generally exist used with any transmitter offered by the same manufacturer. Depending on its construction and features, the price of a ii-in. magnetic flowmeter can range from $1,500 to $v,000. This cost has been coming down but is yet college than that of the least expensive period sensors.

Magnetic flowmeters likewise can be packaged as probes and inserted into process pipes through taps. These probes contain both the electrodes and magnetic coils. The flowing process fluid induces a voltage at the electrodes, which reflects the velocity at the probe tip and not the average fluid velocity beyond the pipage. These magmeters are cheap and retractable. Therefore, the process does not have to be shut down to install or remove them. Metering accuracy is highly dependent on the relationship betwixt the measured velocity and the average velocity in the pipage.

Electrodes

In conventional menstruum tubes, the electrodes are in contact with the process fluid. They can be removable or permanent if produced by a droplet of liquid platinum every bit it sinters through a ceramic liner and fuses with the aluminum oxide to course a perfect seal. This design is preferred due to its low cost, its resistance to abrasion and wear, its insensitivity to nuclear radiation, and its suitability for germ-free applications because there are no cavities in which bacteria can grow. On the other hand, the ceramic tube cannot tolerate bending, tension, or sudden cooling and cannot handle oxidizing acids or hot and concentrated caustic.

In a more than recent capacitively- coupled blueprint, not-contacting electrodes are used. These designs employ areas of metallic sandwiched between layers of liner material. They are available in sizes under viii inches in bore and with ceramic liners. Magmeters using these not-contacting electrodes can "read" fluids having 100 times less conductivity than required to actuate conventional flowtubes. Because the electrode is behind the liner, these designs are also improve suited for astringent coating applications.

Recent Developments

When a magnetic flowmeter is provided with a capacitance level sensor embedded in the liner, it can besides measure the menstruation in partially full pipes. In this design, the magmeter electrodes are located at the bottom of the tube (at approximately one/10 the pipage bore) in order to remain covered past the fluid. Compensation is provided for wave action and scale is provided for full pipe, no flow (static level), and partially filled piping operation.

Some other recent development is a magnetic flowmeter with an unlined carbon steel flowtube. In this pattern, the measuring electrodes mount externally to the unlined flowtube and the magnetic coils generate a field 15 times stronger than in a conventional tube. This magnetic field penetrates deep into the procedure fluid (not just around the electrode as with standard magmeter probes). The chief advantage is depression initial and replacement costs, since only the sensors need exist replaced.

Choosing an Electromagnetic Flow Meter

Magnetic flowmeters can detect the flow of make clean, multi-phase, muddied, corrosive, erosive, or sticky liquids and slurries equally long as their electrical conductivity exceeds the minimum required for the detail blueprint. The expected inaccuracy and rangeability of the better designs are from 0.2-1% of rate, over a range of ten:1 to xxx:1, if the catamenia velocity exceeds i ft/sec. At slower flow velocities (fifty-fifty beneath 0.1 ft/southward), measurement error increases, but the readings remain repeatable.

It is important that the electrical conductivity of the process fluid be compatible. If ii fluids are mixed and the conductivity of one additive is significantly different from that of the other procedure fluid, it is important that they be completely intermixed before the alloy reaches the magmeter. If the blend is not uniform, the output indicate will be noisy. To prevent that, pockets of varying conductivity tin can be eliminated by installing a static mixer upstream of the magmeter.

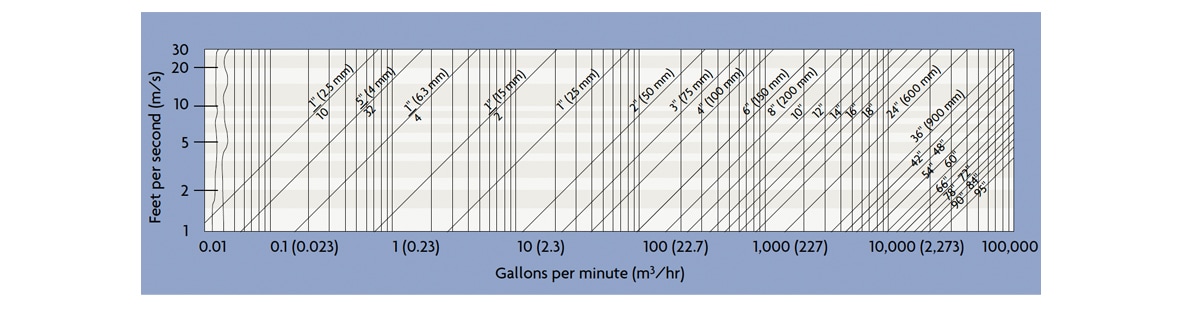

Magmeter size is adamant by capacity tables or charts published past the manufacturer. Figure 4-iii provides a flow capacity nomograph for line sizes from 0.one in. to 96 in. For most applications, catamenia velocities should autumn between 3 ft/sec and xv ft/sec. For corrosive fluids, the normal velocity range should be 3-6 ft/sec. If the flowtube is continuously operated below 3 ft/sec, metering accurateness will deteriorate, while continuous performance exceeding the upper limit of the normal velocity range will shorten the life of the meter.

Effigy 3: Capacity Nomograph for Magnetic Flow Meters

Effigy 3: Capacity Nomograph for Magnetic Flow Meters The obstructionless nature of the magmeter lowers the likelihood of plugging and limits the unrecovered head loss to that of an equivalent length of direct pipage. The low pressure drop is desirable because it lowers pumping costs and aids gravity feed systems.

Problem Applications

The magmeter cannot distinguish entrained air from the process fluid; therefore, air bubbling will cause the magmeter to read high. If the trapped air is not homogeneously dispersed, only takes the course of air slugs or large air bubbles (the size of the electrode), this volition make the output signal noisy or even disrupt it. Therefore, in applications where air entrainment is likely, the meter should exist sized so that the menstruation velocity under normal flow atmospheric condition is 6-12 ft/sec.

Coating of the electrodes is another common magmeter problem. Cloth build-up on the inner surfaces of the meter tin electrically isolate the electrodes from the process fluid. This can cause a loss of signal or a measurement error, either by changing the diameter of the menstruation tube or by causing span and cypher shifts. Naturally, the best solution is prevention. One preventive stride is to size the meter such that, under normal flow atmospheric condition, the flowing velocity will be relatively high: at least 6-12 ft/sec, or as high as practical considering the possibility of erosion and corrosion.

Another method of prevention is to utilize electrodes that protrude into the menses stream to take advantage of the turbulence and washing effect. In more severe service, a mechanical cleaning system can be installed and used intermittently or continuously to eliminate coating and build-ups.

Omega Magmeters

Insertion Magmeters

These versatile, uncomplicated-to-install flow meters evangelize accurate flow measurement over a wide dynamic range in piping sizes ranging from 0.v to 8", satisfying the requirements of many diverse applications. FMG3000 Series magmeters offer a variety of output options for utilize with Omega menstruum instrumentation that has a frequency or 4 to 20 mA output. Flow velocity measurement is compensated for temperature via an integrated temperature sensor.

In-Line Magmeters

The FMG90B Serial electromagnetic catamenia meters are designed for measurement of conductive liquids. The FMG90B magmeters accept no moving parts and a PTEFE lining, they tin handle applications involving wastewater, pulp, food, and slurries.

Low Period Magmeters

The FMG-2000 has no moving parts, and electrodes are designed to discourage fouling. This magmeter requires no maintenance in applications where debris would impede mechanical meters. At that place are no parts to article of clothing out. Minimal straight piping requirements allow FMG-2000 Series meters to exist used in piping configurations where there is piffling infinite between the meter and an elbow. FMG-2000 Series meters are rated IP68 for applications where the meter may be under water up to a depth of 3 thousand (x') for prolonged periods of fourth dimension. Rate and total indication are standard. Rate and total units and pulse output are settable via the front console touch key pad by the user.

Installing an Electromagnetic Flow Meter

The magnetic flowmeter must always be full of liquid. Therefore, the preferred location for magmeters is in vertical upwardly flow lines. Installation in horizontal lines is acceptable if the pipe section is at a low indicate and if the electrodes are non at the acme of the pipe. This prevents air from coming into contact with the electrodes. When the process fluid is a slurry and the magmeter is installed at a low betoken, it should be removed during long periods of shutdown, so that solids will not settle and coat the internals.

If it is essential to drain the magmeter periodically, it should be provided with an empty tube nothing selection. When this option is activated, the output of the transmitter volition be clamped to zero. Detection of empty tube conditions is by circuitry connected to extra sets of electrodes in the flow tube. The empty tube zero feature tin also be activated by an external contact, such as a pump status contact.

Magmeters require v diameters of direct pipe upstream and two diameters downstream in society to maintain their accuracy and minimize liner wear. Liner protectors are available to protect the leading edge of the liners from the abrasive furnishings of process fluids. If the magmeter is installed in a horizontal piping exceeding 30 ft in length, the pipe should be supported on both sides of the meter.

The magnetic flowmeter must exist electrically grounded to the procedure liquid. This is because the magmeter is part of the path for whatsoever devious electric current traveling down the pipeline or through the process liquid. Bonding, past grounding the meter at both ends to the procedure fluid, provides a curt excursion for stray currents, routing them around the flowtube instead of through it. If the system is not properly grounded, these currents tin create a nix shift in the magnetic flowmeter output.

Electrical bonding to the process fluid tin be achieved past metal ground straps. These straps connect each cease of the menstruum tube to the adjacent pipeline flanges, which, in turn, are in contact with the process liquid. Straps are used when the piping is electrically conductive. When the pipe is non-conductive or lined, grounding rings are used. The grounding band is like an orifice plate with a bore equal to the nominal size (inside bore) of the period tube. It is installed betwixt the flanges of the menstruum tube and adjacent process piping on the upstream and downstream sides. The menstruum tube is bonded to the process fluid by existence continued to the metallic grounding rings, and is grounded past being wired to a good usher, such as a cold water pipe.

How Does A Magnetic Flow Meter Register Water Flow,

Source: https://www.omega.com/en-us/resources/magmeter#:~:text=Magnetic%20flowmeters%20also%20can%20be,fluid%20velocity%20across%20the%20pipe.

Posted by: saddlerbeeted.blogspot.com

0 Response to "How Does A Magnetic Flow Meter Register Water Flow"

Post a Comment